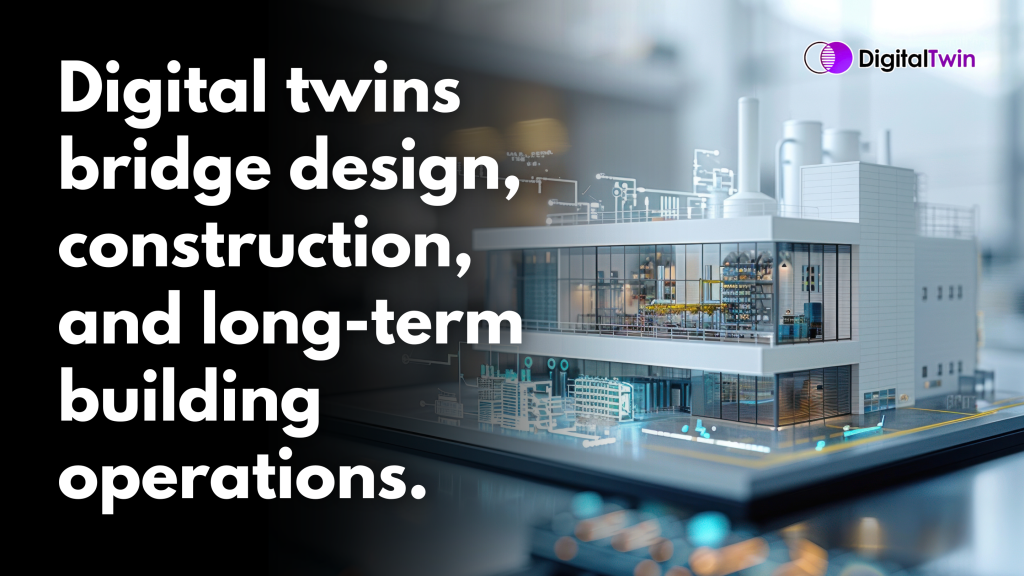

Digital twins are no longer a futuristic concept or emerging experiment. They are now a practical and widely applied tool in modern construction, valued for their ability to improve accuracy, efficiency, and collaboration. While the technology has been around for years, its relevance has become more significant in today’s fast-paced construction environment.

Digital twins serve as reliable, real-time virtual replicas of buildings, enhancing coordination and providing a solid foundation for future management and operations.

Why Digital Twins Matter Today

Construction projects today are more complex, more demanding, and held to higher standards than ever before. Delays and errors can ripple through the entire schedule.

Digital twins help teams manage these challenges through:

1. Better Coordination Across All Disciplines

Architects, engineers, contractors, and project managers can work from one unified model. This reduces miscommunication and eliminates the typical “I didn’t see that change” problem.

2. Early Detection of Design Clashes

Before any concrete is poured or materials are installed, the digital twin reveals conflicts in:

- Structural design

- MEP routing

- Space allocation

- Equipment positioning

Fixing these early prevents costly rework later.

3. More Accurate Progress Tracking

Teams can compare the model with actual on-site status, making delays easier to spot and address.

4. Stronger Planning and Visualization

Stakeholders can fully understand a project before construction begins, improving approvals and expectations.

Today’s construction projects require precision, and digital twins provide it.

How Digital Twins Create Value for the Future

What makes digital twins truly powerful is their impact after construction is completed. They become a long-term tool for building management and operational efficiency.

1. Predictive Maintenance

Systems can be monitored through the digital twin to:

- Predict failures

- Plan maintenance schedules

- Extend the lifespan of building assets

This reduces downtime and unnecessary repairs.

2. Smarter Facility Management

Facility teams gain access to:

- Complete building history

- Utility pathways

- Equipment specifications

- Maintenance records

This makes operations faster, safer, and more cost-efficient.

3. Energy and Environmental Optimization

Digital twins can analyze:

- HVAC performance

- Power usage

- Lighting efficiency

- Long-term energy patterns

These insights reduce consumption and operational costs.

4. Easier Renovations, Expansions, and Upgrades

Instead of starting from scratch, future teams can refer to the digital twin as a detailed reference of the building’s structure and systems.

Digital twins bring lasting value because they support the full lifecycle of a building, from design to construction to decades of operation.

They help owners, developers, and facility managers:

- Reduce long-term operational costs

- Improve safety and efficiency

- Make better-informed decisions

- Extend the usable lifespan of the structure

That’s why digital twins remain indispensable today and continue to shape smarter, more efficient buildings for the future.